- News

- HMK - Machine Building North

HMK to showcase KeDrive D3-AC, plus more cutting-edge automation solutions at Machine Building North 2025

The HMK Team is gearing up for Machine Building North 2025, taking place at the Concorde Conference Centre in Manchester on Thursday 10 April.

As the only event in Northern England dedicated entirely to machine building and factory automation, this one-day exhibition is a must-attend for machine builders, OEMs, systems integrators, and factory automation professionals. With leading suppliers, technical experts, and the latest innovations all under one roof, attendees will gain valuable insights and solutions to help tackle their automation challenges.

Visit the HMK Team at Stand 113 to discover how we combine world-class products with engineering expertise and support to simplify automation, reduce risk, and accelerate success.

Showcasing the KeDrive D3-AC – Motion delivered efficiently

At this year’s event, we are proud to introduce the KeDrive D3-AC from KEBA, a game-changing and highly efficient multi-axis servo drive designed to reduce panel space, installation time, and complexity.

The KeDrive D3 drive system delivers an all-in-one, efficient solution for multi-axis applications with a robust combination of hardware, software, and services. Its drives, motors, and safety technology are seamlessly integrated and adaptable to meet varying application needs:

- Compact, gapless form factor

- 1-, 2- and 3-axis drive modules from 1.5-250 Arms

- 300% overload capability

- Integrated SIL 3 Safety

- Energy-efficient solution, active infeed, kinetic buffering

- Profinet IRT and EtherCat interfaces

Launching at the show, the all-new KeDrive D3-AC takes efficiency to the next level by integrating 3 axis drives and supply into a single compact unit. With panel space and installation time being critical cost factors, the D3-AC delivers game-changing benefits, including:

- Typically, half the panel space required

- A third of the wiring time of its discrete alternative

- Lower material usage per axis for improved sustainability

- Single set of line-side components

- Reduced testing time

- Lower unit cost

- Faster installation with a single common AC supply

With KEBA’s 50-plus years of automation expertise and HMK’s engineering know-how, the KeDrive D3-AC is the ideal choice for machine builders looking to enhance efficiency, reduce costs, and simplify implementation - all without compromising performance.

Austrian manufacturer KEBA develops and produces pioneering automation solutions for a wide range of industries, guided by their company motto - ‘automation by innovation’. Find out more

HMK established a partnership with KEBA last year in response to the evolving needs of our OEM customers. This collaboration enables us to meet the growing demand for cost-efficient, open platforms with EtherCAT communications capabilities, ensuring smooth and stress-free solutions for our customers.

Gary Kitchin, Managing Director at HMK Automation, said: “We’re excited to showcase the KeDrive D3-AC as our star product at Machine Building Live North 2025. This innovative servo drive brings efficiency, cost savings, and simplified installation, making it a real game-changer for machine builders looking to simplify automation. The KeDrive D3-AC coupled with HMK’s knowledge really does delivery motion efficiently.

“Alongside the KeDrive, we’ll also have a range of other cutting-edge products on display from our industry-leading partners, including Siemens and IMI Bahr, showcasing the very latest in automation technology and innovation.

“At HMK, our mission is to combine world-class products with expert engineering to simplify automation, reduce risks, and drive success for our customers, so we look forward to demonstrating how we can help machine builders enhance efficiency and stay ahead of the competition at Machine Building North 2025.”

Other industry leading products the HMK Team will be showcasing include:

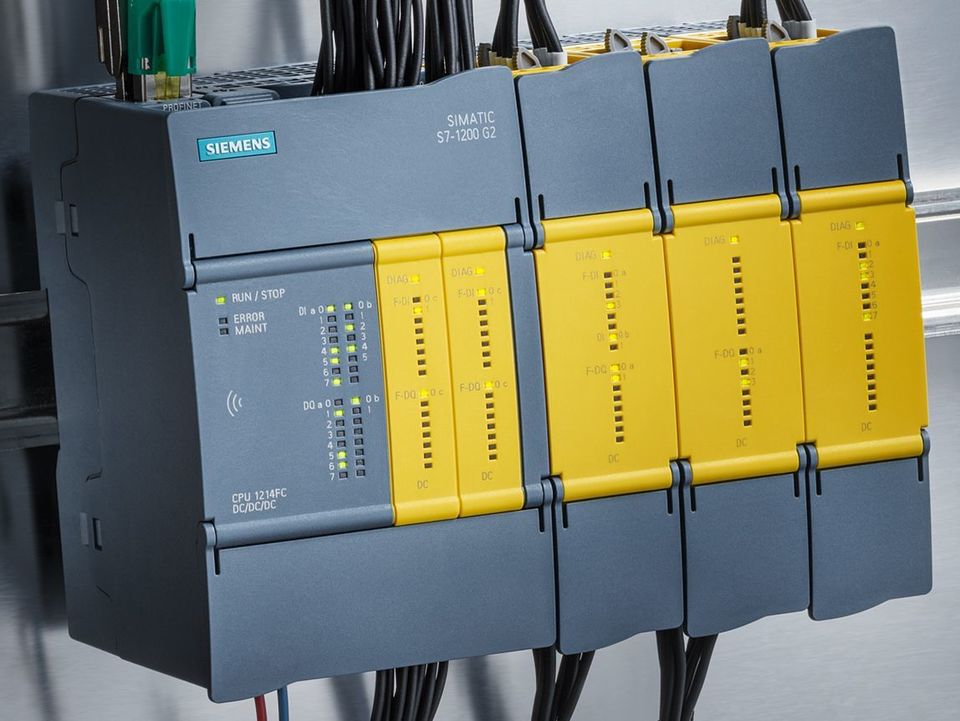

Siemens S7-1200 G2 – A modular controller designed for flexible and reliable automation in various industries. It offers high performance with integrated Ethernet communication, an intuitive user interface, and modular expansion options. The system supports advanced functions such as integrated motion control and safety features, making it ideal for smaller to mid-sized automation tasks. Its open architecture allows seamless integration with other Siemens systems, enhancing flexibility and ensuring smooth scalability.

Find out more

IMI Bahr Linear Guides – A cost-effective linear motion solution designed to meet the needs of OEMs. Complementing our high-performance Schneeberger Ball and Roller Rail range, IMI Bahr’s ball rail product offers reliable performance at a competitive price point. Widely used across the US and Asia, they comply with international standards, enabling seamless integration without design change. Ideal for general linear applications, they provide an efficient and accessible option for machine builders looking to optimise cost and performance.

Find out more

Visitors to Machine Building North can also look forward to a day packed with innovation, expert-led discussions, and the opportunity to connect with leading suppliers in machine building and automation. With live demonstrations, technical insights, and hands-on access to the latest technology, the event is designed to provide practical solutions to real-world automation challenges.

As a unique bonus, attendees can also take advantage of free guided tours of the iconic Concorde aircraft, making this an unmissable event for anyone in the industry.